Profile: Haresh Lalvani

Digital Futures Group | On 16, Mar 2013

We are pleased to be able to share the Profile on Dr.Haresh Lalvani of Pratt Institute that was originally posted on core.form-ula Dr.Lalvani has spent the last 30+ years building an incredibly rich body of work that has pushed design to new limits. Dr.Lalvani has been working on many ideas through out his career, this a small percentage of this work within this profile. Over the course of the next few weeks, they will introduce some more experimental work coming out his Morph Studio and Milgo-Bufkin and you will be able to see it oncore.from-ula.At the Morphology Studio, the intersection between design and technology is dealt with everyday to create new architectural surfaces and spaces that can be realized, not just imagined. The ability of the Morph Studio to prototype ideas is a unique opportunity, one that we all strive for as designers to have. I have been very lucky to have taken his Pratt studios and be involved with his Morph Studio since 1998; I know many of the generations of Pratt students alike have been greatly influence by his teachings as well. Enjoy

(Text by Haresh Lalvani; excerpted from the AD book The Organic Approach to Architecture, eds. Deborah Gans and Zehra Kuz, 2003, Wiley-Academy))

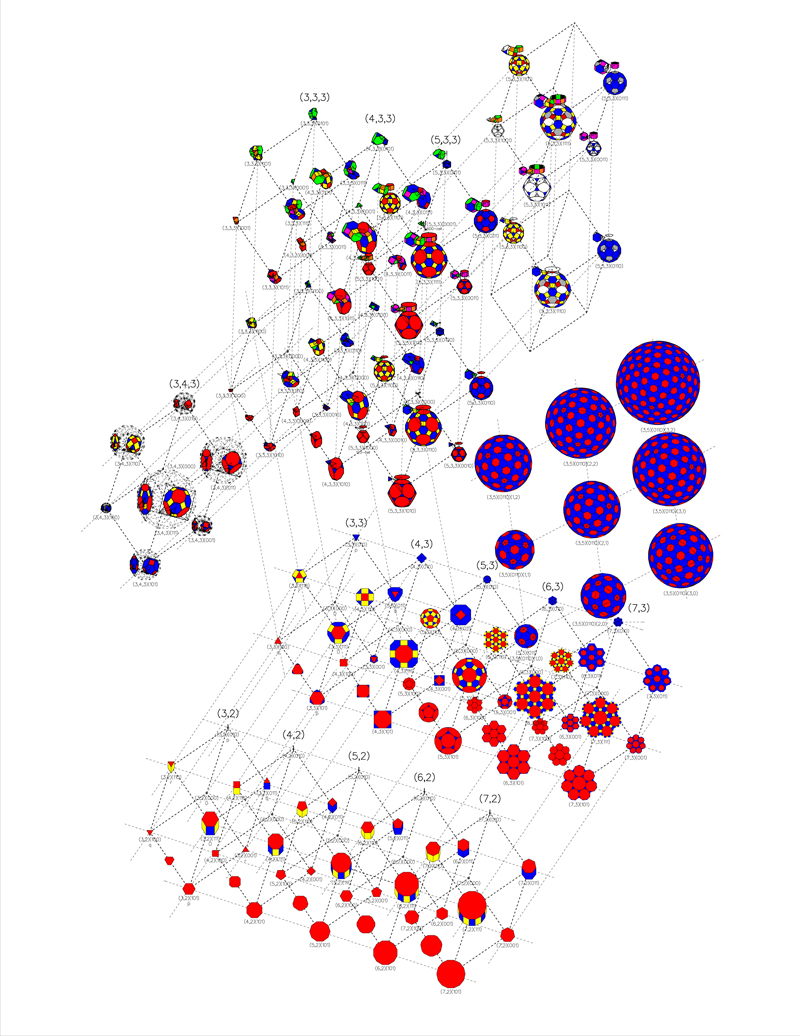

Genomic architecture – Genomic architecture is based on the manipulation of the architectural genome. Like its biological counterpart, this genome is universal and encompasses all architecture — past, present and future. At its root, this genome is defined by a unified morphological genome, a universal code for all morphologies — natural, human-made and artificial. Morphogenomics, a possible new science, deals with morphological informatics. It includes mapping the morphological genome as a basis for generative morphologies that underlie the shaping of architectural space and structure. Once mapped, the morphological genome will need to be layered with other genomes (also requiring mapping) to cover different aspects of architecture: physical (e.g. materials, construction technologies), sensorial, cognitive and behavioral. Genomic architecture, based on the layered genome, encompasses an integrated world of “artificial architecture” (used in the same sense as “artificial intelligence” and “artificial life”), a world of complexity evolving in parallel with the natural world. It is a morphologically structured network of information that determines architectural taxonomies and phylogenies, permits digital manipulation of form in the design process, and enables mass-customization in digital manufacturing.

Limits of Organic Architecture – The meaning of the term “organic architecture”, which draws its inspiration mostly from biology, keeps evolving with increasing knowledge of nature combined with foreseeable technologies. As new technologies emerge, architecture becomes more organic in its scope, intent and realization. The upper limit to this sort of bio-mimicry would be biology itself. Buildings would grow , respond, adapt and recycle, they would self-assemble and self-organize, they would remember and be self-aware, they would evolve, and they would reproduce and die. Organic architecture, were it to attain biology, would design itself. It would also perpetuate itself. Architecture would then become “life”, and paradoxically, buildings would no longer need architects. Organic architecture, in this limit case scenario, would also define the end of architecture (as we define it now).

Extrapolating from projected technologies of the future , a scenario like this one is quite possible, even inevitable, but it is flawed for two reasons. First, biology as a goal for organic architecture assumes that such a biology (namely, existing biology) is frozen in time since it is based on “life” as we know it presently. Extrapolation of architecture from present biology ignores past and future biologies. Nature’s ongoing experiment comprises structures that are extinct, structures that exist now, and structures that have yet to appear. The definition of ‘organic’ must thus encompass all biologies: past, present and the future. Second, it ignores the creation of the new, e.g. new materials (new chemistries) not found in nature, new technologies not found in nature and new organisms (based on known or new biologies) not existing in nature. Besides new natural biologies, the term ‘organic’ must thus include artificial biology as well. This is where the line between human designs and those made by nature becomes a continuum.

What unites the natural and the human-made (including the artificial) are fundamental laws, the laws of nature. Our knowledge of nature and human-made constructions evolves such that these laws become increasingly more encompassing, tending towards the natural upper limit of a single unifying law for everything (as in the current search in physics, for example). Whether this limit is attainable is an open question. The natural and the artificial are facets of organic architecture that are joined at this fundamental level. This is true of biology and buildings. The morphologic possibilities within these two worlds fall within a single morphological universe governed by unifying laws of form that are common to both. It is governed by the mathematics of space, structure and form. When physical constraints (size, material, movement, weight, stability, building method or forming process, etc.) are imposed on form, this universe shrinks through the elimination of mathematical structures that are physically unrealizable. The physics and chemistry of form delimits the morphological universe.

- The expensive–and comparatively slow–press brake machine could be made obsolete by Milgo/Bufkin’s AlgoRhythms Technologies. Photo:Robert Polidori for Metropolis

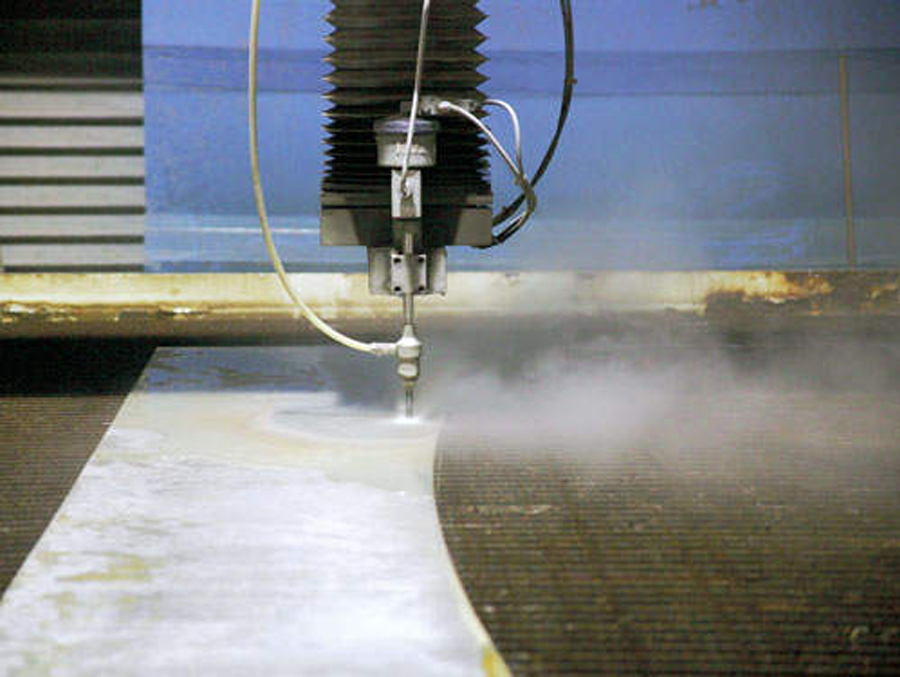

The computerized water jet cutter (above) and the laser cutter, some of the factory’s sophisticated fabricating tools. Photo: Robert Polidori for Metropolis

Following is the article from Metropolis magazine (Bend the Rules of Structure, By Peter Hall), June 2003, describing Lalvani’s collaboration with Milgo, A Brooklyn metalworking shop with an unlikely name may hold the key to 21st-century shapemaking. As company names go, Milgo/Bufkin sounds almost Dickensian. Pushing open the hefty rust-coated steel door of the company headquarters, I half expect to be greeted by a scrawny Mr. Milgo and a plump Mr. Bufkin, with polished bald heads and prominent nose hairs. The truth is almost as good. The Milgo/Bufkin factory, founded in 1916 in a toxic corner of industrial Brooklyn, is where the drawings and doodles of designers and sculptors are turned into palpable reality. It is the art-and-architecture world’s little secret. The chief of this family-owned business is not a Milgo or a Bufkin, but Bruce Gitlin, who offers a hearty handshake and speaks in an accelerated voluminous manner as if someone might be about to interrupt him. “The name never meant anything to me,” he says, adding that Milgo/Bufkin is a fabrication (appropriately enough), a conflation of an off-the-shelf company name Milgo Industrial and Bufkin Enterprises, named after all the first initials of his children, nephews, and nieces. In the last 40 years the firm has built work for the whole canon of art sculptors: Donald Judd, Claes Oldenberg, Jeff Koons, Richard Serra, Robert Indiana, and Matthew Barney. It has fabricated the metalwork in some of New York’s best-known lobbies, entrance doors, and facades–including Tiffany’s, Bloomingdales, Lever House, Trump Tower, the Ford Foundation–and that large number “9” outside 9 West 57th Street. And this is only the beginning of the tour.

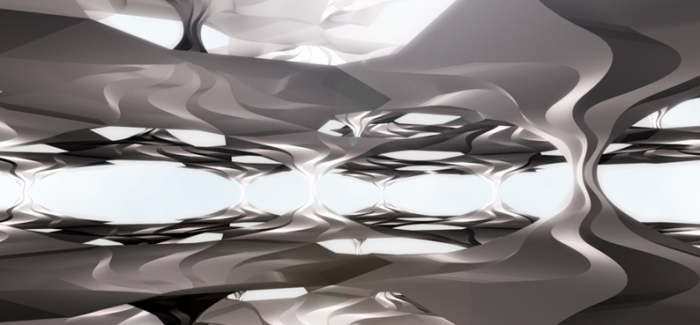

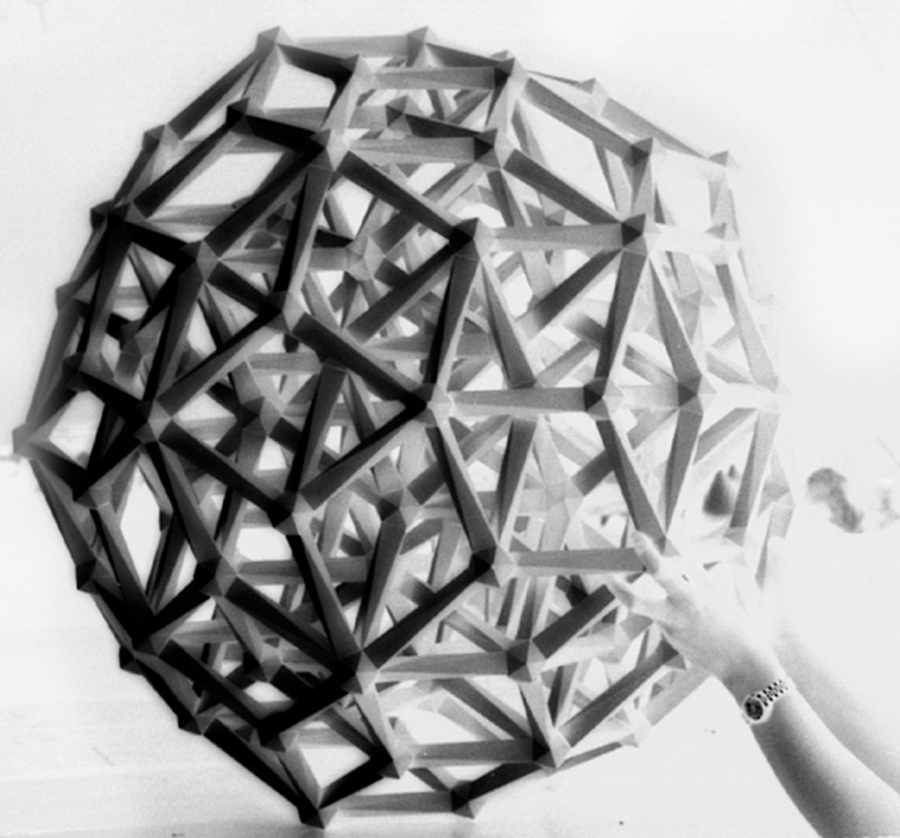

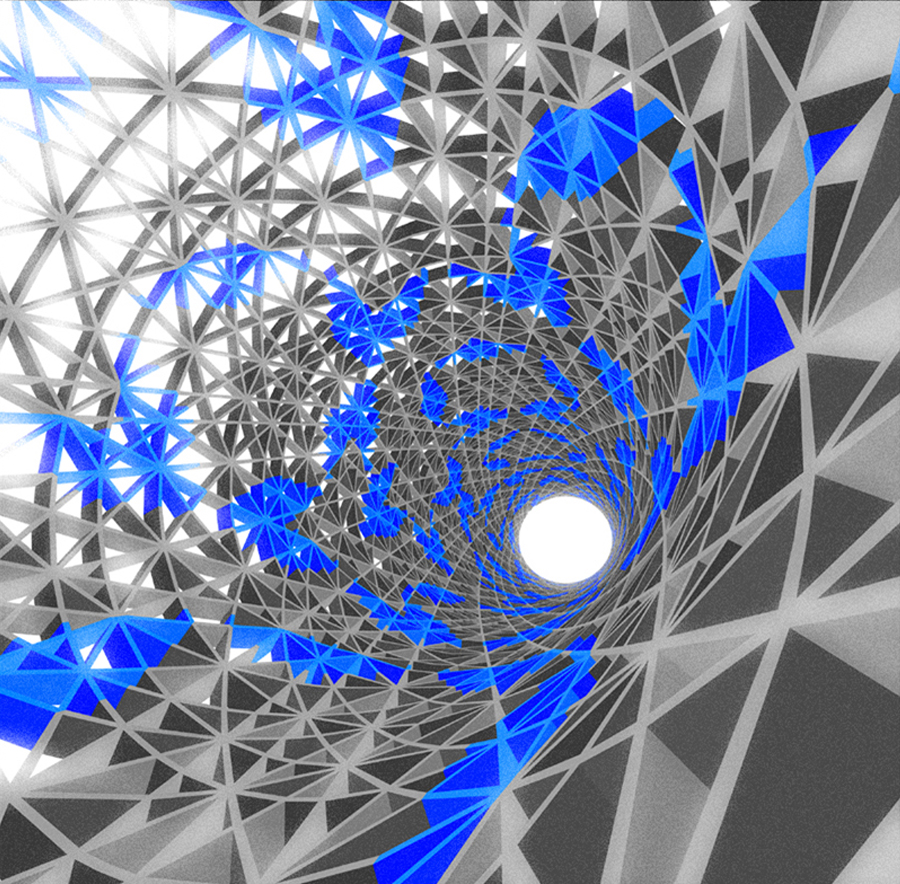

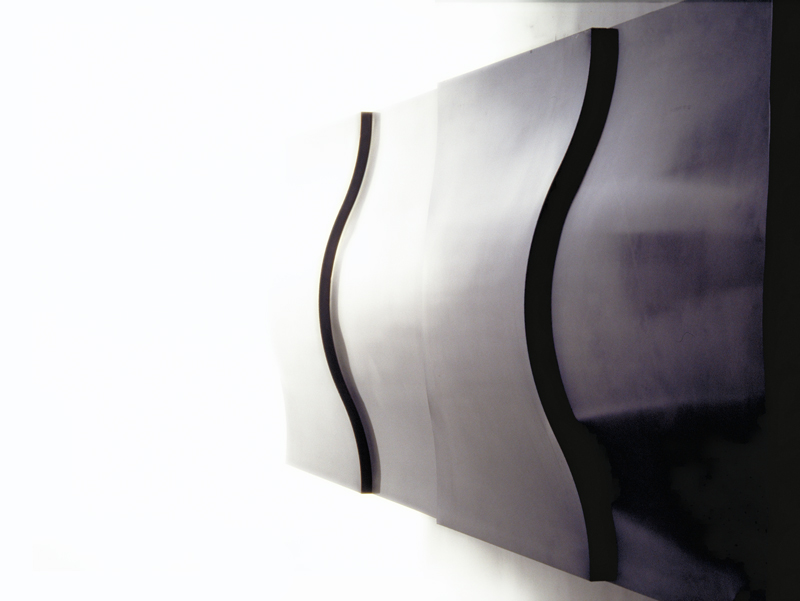

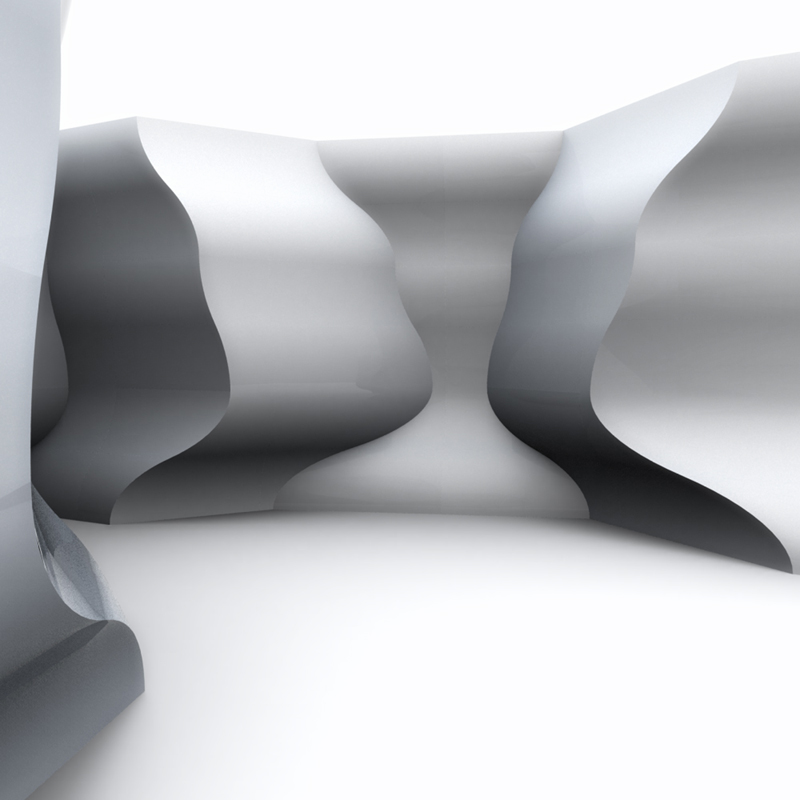

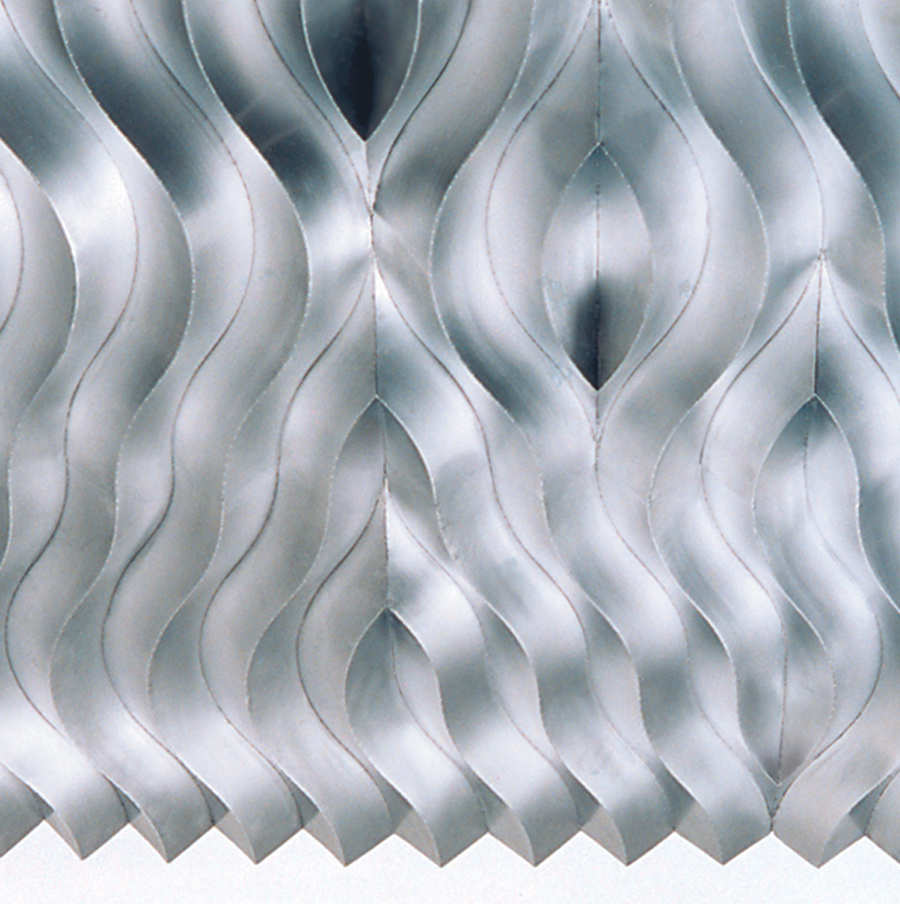

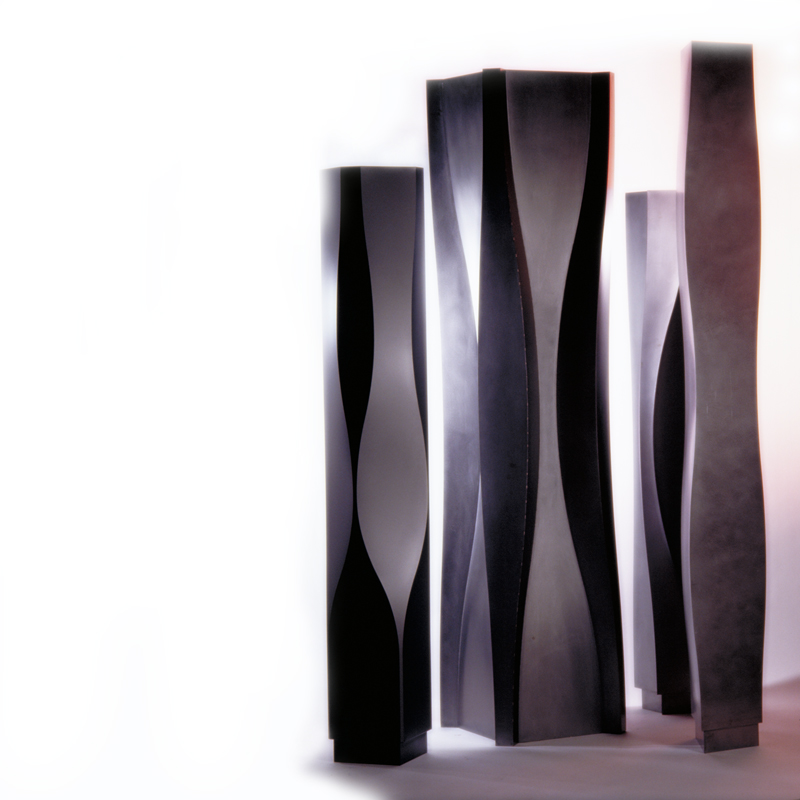

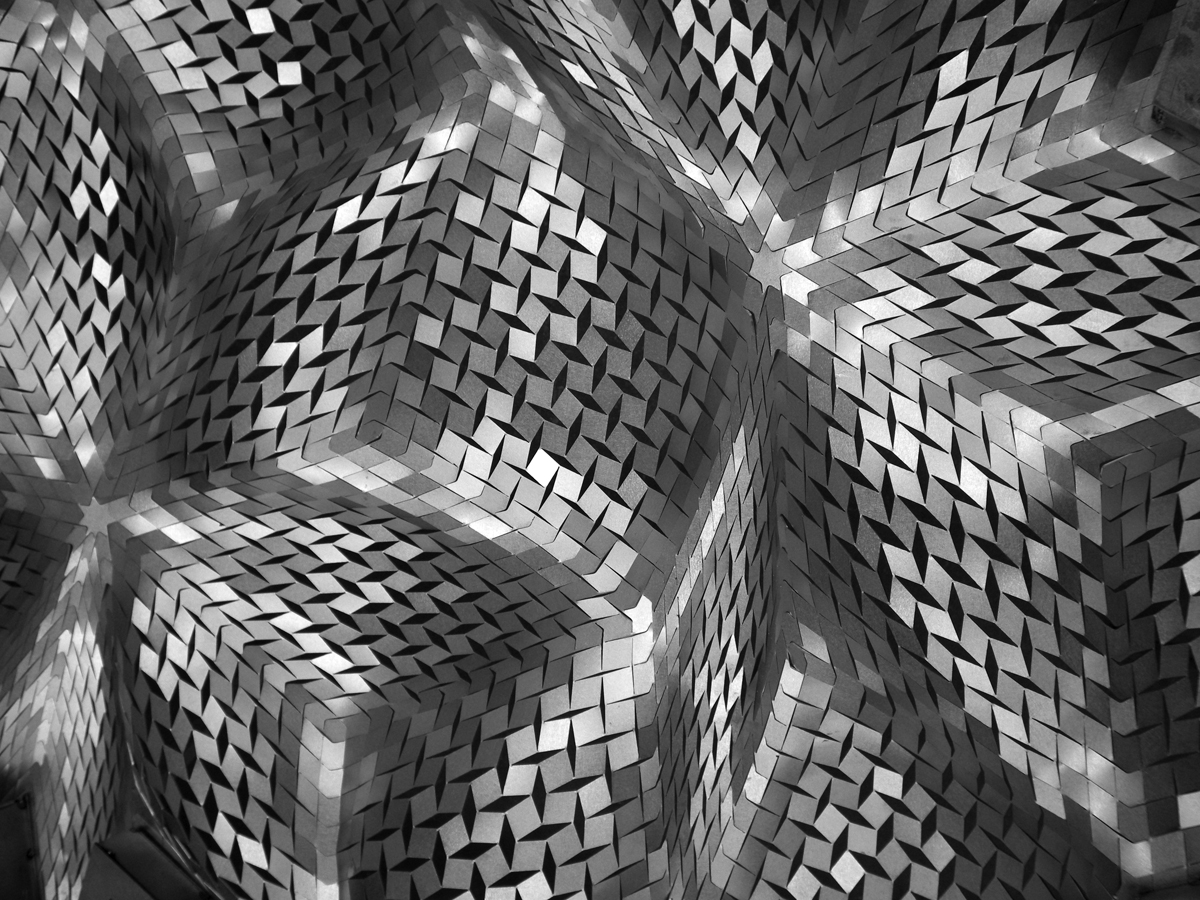

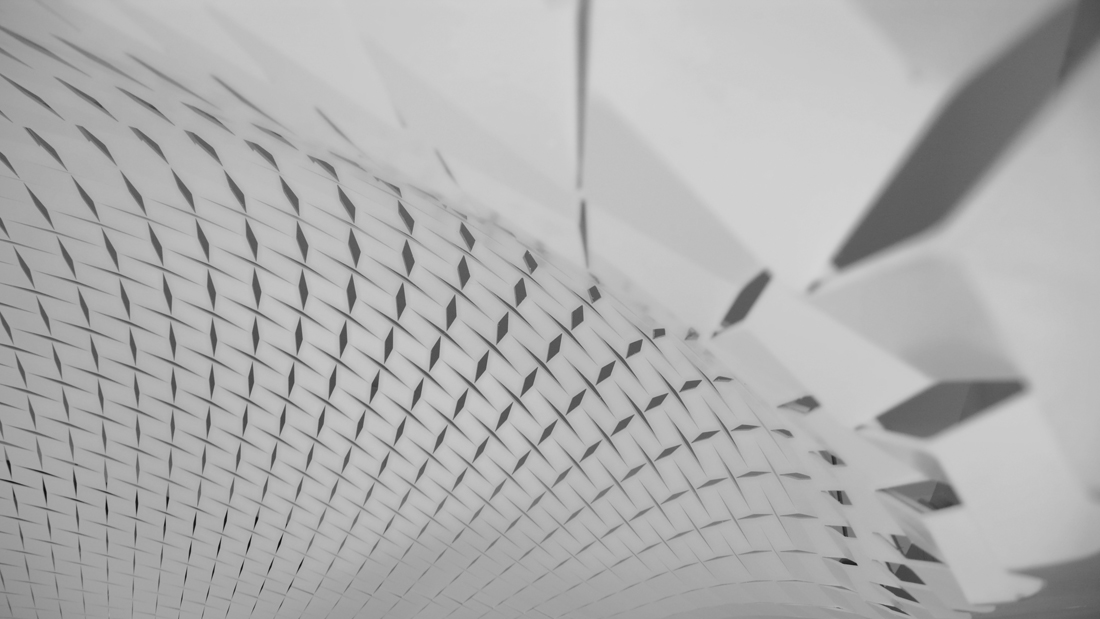

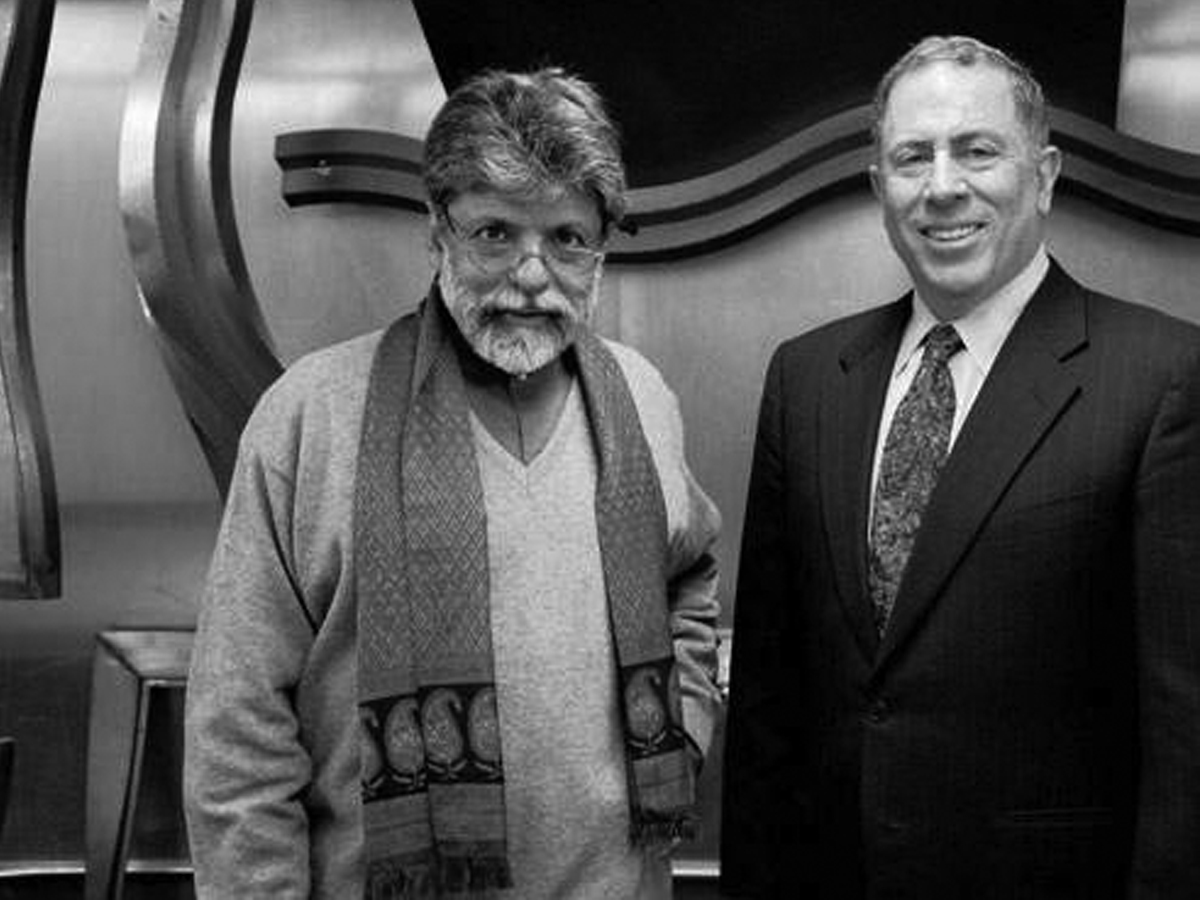

Gitlin is about to show me a project that he believes will “change all manufacturing in the world.” The brain behind the manufacturer’s bravado waits in the company boardroom–a scholarly figure with a salt-and-pepper beard and a scrutinizing bespectacled gaze. Haresh Lalvani is a professor of architecture at Pratt Institute and a self-described “architect-morphologist.” Together Lalvani and Gitlin have invented AlgoRhythms, a bad pun but a unique initiative involving some large bending machines, a grand theory, and, well, the future of architecture. AlgoRhythms describes a method for folding a single sheet of metal into complex and elaborate forms, based on Lalvani’s calculations. By way of introduction, Lalvani borrows a sheet of paper from my notebook. The structural engineer Robert Le Ricolais, he explains, established that “by crushing structures we reveal what they want to become.” Lalvani rolls the sheet of paper into a cylinder and then strikes it sharply at the top with the heel of his hand. The cylinder crumples at the center, creating several apparently random folds. To Lalvani these are not random, but the key to the underlying deep nature of structure. “Any skin under some sort of force wants to take on a natural pattern,” he says. “These patterns have some morphological laws. We are working with that idea and applying it to metal.”The first AlgoRhythms prototypes are arranged around the table and propped against the walls of the studio. There is a ceiling panel of rippling steel, an undulating wall panel, and a series of steel maquettes of column covers that curve and flow in waves. Though the twisting metal might remind one of the by now near merchandised signature of Frank Gehry, they’re not derived from one man’s intuitive sense of proportion or aesthetics but generated from algorithms based on Lalvani’s architectural “genetic code.”

For more than 30 years Lalvani has located his career at the intersection of architecture, nature, and higher mathematics, where, he says, he is working to “decode the architectural genome” and discover the elemental principles underlying natural and artificial form. In other words, DNA, nature’s building blocks, has a counterpart in the artificial world that can be used to generate structures. Thrust across the meeting table is one of Lalvani’s many diagrams of these structures, showing progressive variations–in several dimensions–of the Buckyball, the 60-atom carbon molecule shaped like a soccer ball (named by scientists after R. Buckminster Fuller’s geodesic domes). Lalvani began identifying such variations on a theme at Pratt in the early 1970s, and in the early ’80s he developed a code for generating variations of Islamic motifs. At Milgo/

Bufkin he has applied automatic shape making to metal manufacturing. Setting out to modulate a stiff metal surface into several rigid curved surfaces without weakening the material, Lalvani developed a series of algorithmically generated geometries. These were then translated (by a former student, Neil Katz) into computer models and fed into computer-controlled machinery that marks and laser cuts sheet metal and readies it for folding (which is currently done manually).

Gitlin holds up a large piece of metal with corrugated curves. “I can only do this with the formulas that Haresh gives me,” he says. “There’s a whole new body of shapes and forms that have come out of his work that allows us to do things that have never been seen before. It’s opened up the design palette enormously.”

Lalvani does not stop there. He argues that if his artificial genetic code were to be combined with biological or physical building processes, buildings could eventually be “grown” into any desired shape. Architecture would be able to design itself. Lalvani is not the first theorist to propose self-generating buildings. His Pratt colleague William Katavolos introduced the idea of growing architecture more than 40 years ago in his book Organics, and more recently architect John Johansen has proposed that with molecular engineering atoms can be encoded with shape information that would permit controlled self-production. But Lalvani appears to be the first to provide a systematic means for this to happen, by borrowing from biology the conceptual model of the genome. This presumptuous adaptation would strike some scientists as audacious, pointless, or even insane. Mathematicians would not be troubled by using algorithms to generate forms, but might balk at the idea of Lalvani’s “hyperuniverse of form,” where all patterns are indexed within a unified database. Indeed wading through one of Lalvani’s papers, replete with his idiosyncratic phrases–his “architectural genome” and “morphological universe”–can be a bewildering experience. But Lalvani has done some homework. Loren Day, a virologist and research professor at New York University School of Medicine, met Lalvani recently and was surprised by the extent of his understanding of molecular biology. “I must say Haresh is very familiar with much of the work being done in viruses,” Day says, adding that Lalvani’s knowledge of the morphology of viruses, most of which are structured like Buckyballs, led him to the concept. As for the validity of applying the genome to artificial forms, Day offers cautious confidence. “I wouldn’t say it’s valid, but it’s very useful as a broad concept–the idea that one can break down forms into their elemental components, which are the building blocks. If I understand it correctly, you apply simple rules to these building blocks and generate remarkably diverse structures. And Haresh is doing just that.”

Whether or not Lalvani’s AlgoRhythms are the first pillars of a self-constructing citadel, they have immediate potential to structural engineers like Vincent DeSimone, whose firm has worked on a number of Gehry buildings. “If you take a piece of steel and bend it, it gets an inherent strength out of the geometry of the bend,” DeSimone says. “A lot of times when you want to make a warped surface in metal you literally have to stretch it. Lalvani’s algorithms have given you a method where, by folding along perforations, the metal is never stretched.” The distinction between AlgoRhythms and the sculptural steel surfaces of Gehry’s building, DeSimone says, is that “Gehry’s is a free-form surface; Haresh’s is a 3-D solids model.” At Gehry’s new Fisher Center for the Performing Arts, at Bard College, for example, the undulating stainless-steel roof functions as a rain and snow shield, but the load is carried by a series of ribs underneath–the “real roof,” as DeSimone puts it. With Lalvani’s technique, in theory an entire building could be made of load-bearing folded metal.

The difficulty with using metal for structure is that it has a tendency to perform badly in the intense heat of a fire. DeSimone proposes filling the folded metal forms with concrete. “The panel would be an external form of reinforcing,” he says. “You could come up with a designer’s dream, which would be an exposed structural-steel metal building.” He adds, “I can see walking into a building where the lowest structural columns are magnificently folded pieces of titanium and they’re real: the titanium is not just an appliqué but integral to the strength of the concrete.”

Gitlin drives me in his Range Rover toward the Milgo/Bufkin “art shop,” where the AlgoRhythms are fabricated. Through the car windows are the bleak industrial hinterlands of Brooklyn, which have been stamped out of once fecund farmland by a succession of manufacturing industries. Shipbuilding gave way to printing, pottery, glass, ironworks, and finally, oil. When a refinery opened in Greenpoint in 1867 and began draining its refuse into the nearby creeks, the local fish and blue crabs promptly expired, as did most traces of organic life. It seems ironic that the molecular structure of nature might now provide the key to the future of the built environment. Gitlin’s Russian immigrant grandfather founded the company as a wooden carriage-making shop in 1916. That business dwindled, and the firm, then named Builtwell, turned to making horse-drawn wagons, which were shortly thereafter eclipsed by the motor car. After the depression the firm switched to making truck bodies, another tough business. Gitlin says his grandfather would collect overdue payment armed with a crowbar. When his father took over, most truck buyers were Italian-Americans, and many of his customers seemed to have Mafia connections. In 1963 Gitlin walked in, age 21, armed with a metallurgical engineering degree, and told his father to dump the lot and move into high-end architectural metalwork and art fabrication. “I had no customers–no work–but my father believed in me,” Gitlin recalls. “I didn’t know what the hell I was doing, but we changed the whole business.”

We arrive at an intersection outside the art shop, an area Rem Koolhaas might call “junkspace.” Across the street is Gotcha Auto Salvage and Acme Steel Doors. The art shop is a nondescript brick warehouse building with a giant billboard on its roof, positioned for the benefit of drivers on the Brooklyn Queens Expressway, which roars overhead. The word Milgo is daubed crudely in paint above the door. Stepping through the door, however, is like entering a fantastical grotto of shining steel, bronze, and oxyacetylene. A technician is filing a small bronze sculpture. Sparks fly from the dark corners of the shop. Shoved against a grille-covered window is a steel tree with perfect shining petals. A packing crate lying casually on the floor bears the stenciled letters “JUDD–RED COPPER PROGRESSION 1985.” As we move toward the back of the shop Gitlin points out a 15-foot-high John Romandi piece named Pyre, and introduces me to the head of the art shop, a looming figure with an iron handshake. Alex Kveton showed up at Milgo/Bufkin’s door one day in 1983, according to Gitlin, and said, “I’m here to work for Milgo.” A renowned sculptor in Czechoslovakia, Kveton and his wife had fled the country and come to Greenpoint with only one goal: a job at Milgo/Bufkin. Gitlin asked how he knew about the firm. “Everybody knows about Milgo,” Kveton said. “I read the art magazines.” Kveton continues to work as a sculptor (a metal headless horseman currently sits in the shop waiting to be shipped to its client, the town of Sleepy Hollow) but is also responsible for turning Lalvani’s research ideas into metal. I ask him what was the biggest challenge of the AlgoRhythms project. “Figuring out how to make it,” he says bluntly.

Lined up side by side, the full-size 12-foot-high AlgoRhythms columns begin to reveal their power as mutable forms. They make a curious platoon, twisting and rippling like some sort of dramatized baroque rebuttal of the machine age’s claim to a rectilinear world. But I am struck by how easily Lalvani and Gitlin’s grand project might be limited by this array of curving steel, how Milgo/Bufkin might be pigeonholed as providers of fancy metal coverings, the stamped tin ceiling of the twenty-first century. Lalvani is anxious that his work not be portrayed as the development of trendy shapes; this is an entire system for generating infinitely variable form. Like Fuller before him, he cleaves to the idea that when science begins to mimic nature at a molecular level, it moves into a realm outside of fashion. When I raise the possibility that AlgoRhythms might be a victim of architecture’s fickle aesthetics, he protests: “How can you say that life will become outdated?” He concedes that “there’s a danger that if we restrict ourselves to metal it will have a certain life span–and that’s purely circumstantial.” He adds, “This is just one case study.”

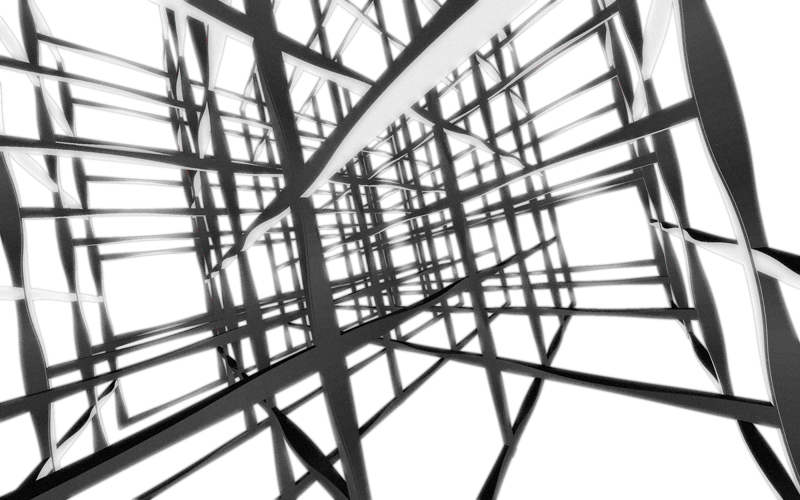

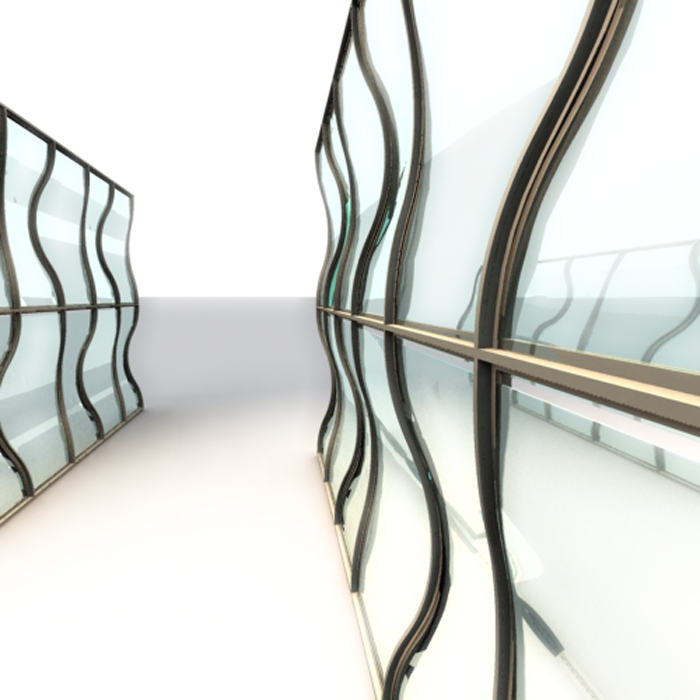

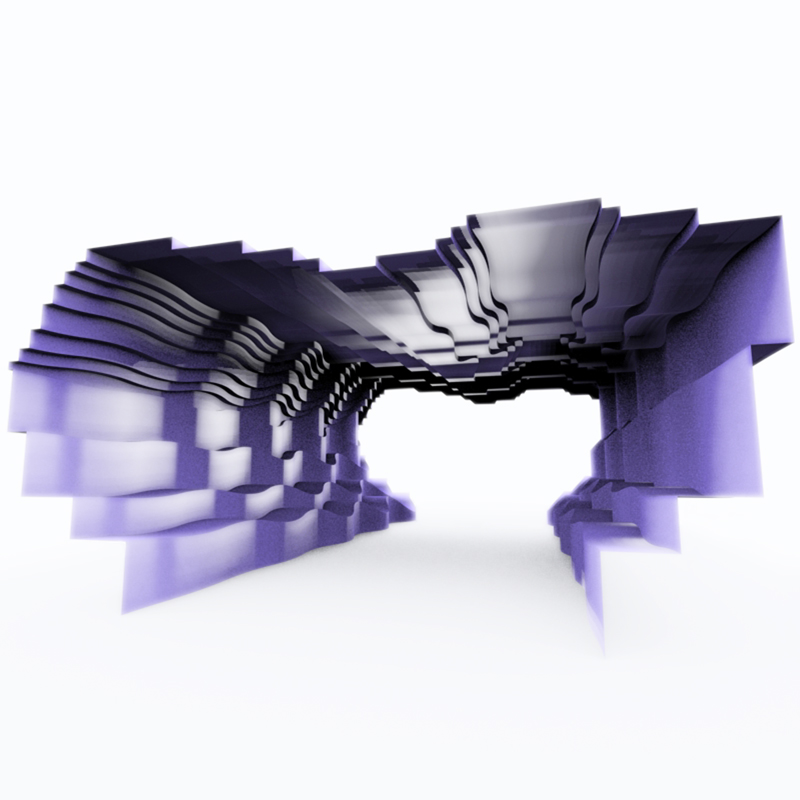

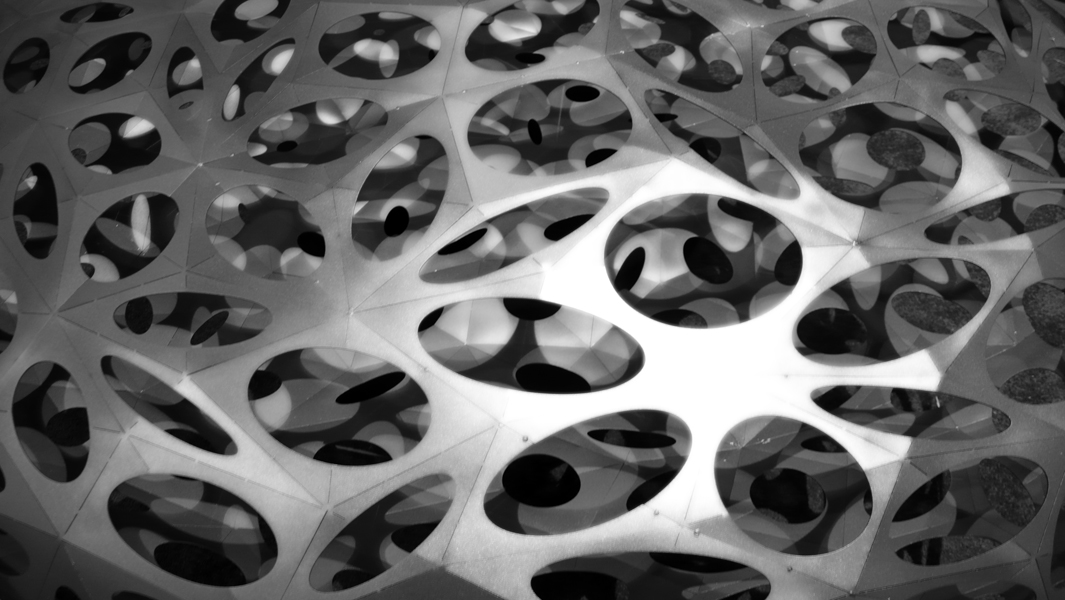

Lalvani and Gitlin are already at work on another project they refer to as “universal skin.” Though reluctant to divulge details, they hint at a technique whereby any sheet material can be morphed and expanded into any shape following Lalvani’s algorithms. At the more speculative end of his design work, Lalvani has rendered entire virtual environments of morphologically encoded structures. A Column Museum proposes a space filled with a sampling of all possible architectural columns past, present, and future, arranged as physical display or in virtual space with numerous entrance and exit points. The dazzling Waveknot proposes opaque corrugated glass-and-metal modules forming an undulating surface defined by a simple knot, such that the surface becomes both inside and out.

In five years, Lalvani says, enough of the morphological genome will be mapped and the project will have a strong enough scientific foundation to make it publicly available to other researchers to help advance. “First I want to make sure it has a foundation,” he says. “When it’s grounded in mathematics, you’re not just giving an opinion.” The project certainly won’t fail for lack of conviction. When Gitlin was first introduced to Lalvani by his friend and colleague John Lobell in 1996, Gitlin listened to Lalvani for “about five minutes,” he says, and knew he was ready to collaborate. Gitlin’s next hurdle, however, is to finance the manufacture of machinery that can mass-produce–or mass-customize, rather–the AlgoRhythms. So far most of the project has been funded out of Milgo/Bufkin’s coffers. One scheme received additional support from Pratt and a two-year grant from NYSTAR (New York State Office of Science, Technology and Academic Research). Gitlin is discussing partnerships with two research-heavy universities. The result, he imagines, would be a giant “organic machine” capable of producing sections, seats, cars, even tunnels. Lobell adds that mass customization will present designers with the ultimate ideal: “The designer logs in, sees an image on-screen, starts pulling and distorting it with the mouse to get exactly what he wants, clicks, and the design goes straight to a laser cutter. It’s FedExed to him the next day.” As for the fashionable nature of the project’s implied themes, Lobell–an architect–has no qualms. “The current demand of the profession is for curves,” he says ironically.

Alicia Imperiale, an architectural theorist and author of New Flatness: Surface Tension in Digital Architecture, believes there is a link between Lalvani’s work at Milgo and the architecture of Herzog and de Meuron, Greg Lynn, and Foreign Office Architecture (notably their Yokohama Terminal project). Lalvani, she notes, has arrived on similar terrain from a different starting place. “He has found a logic between morphological change–the way something looks–and how it performs,” Imperiale says. “Because of his understanding of the fluid dynamics of surface, he’s able to manipulate that and use the forces to let it support and sustain itself. I find that compelling and efficient. I would love to see how an environment would be made with these forms.” The distinction between Lalvani and his more celebrated peers in the realm of commercial architecture is that he did not set out to translate postmodern ideas into headline-grabbing buildings. His goal was simply to continue his graduate studies. The incentive to put theory into practice came from more practical considerations. According to Gitlin, Lalvani wanted to send his son to private school and couldn’t afford to. Gitlin says this with the affable swagger of a Brooklyn businessman. The more measured but beguiling delivery of Lalvani, the academic immigrant from India, makes a striking contrast. They’re an odd pair. But it’s encouraging to think that pure research has met a real-world partner in the form of a family-owned metalworking shop in Brooklyn. Toward the end of my visit Lalvani takes me out to get coffee from a stainless-steel canteen truck parked under the expressway to serve local factory workers. He tells me, with a gleam of delight in his eye, that he thinks of Milgo/Bufkin as “romantic.” For a theorist immersed in one field for decades to suddenly see his ideas made manifest must be a rewarding experience. As for Milgo/Bufkin, it’s a collaboration that could take the venerable Greenpoint firm well into the twenty-first century.

Xurf Ceiling Light Fixture (2009), Na Ok Woo Conference Room, School of Architecture, Pratt Institute (with architect Richard Scherr). Photo: Ajmal Aqtash.

Lalvini (above, on the left) stands with Milgo/Bufkin chairman Bruce Gitlin in front of AlgoRhythms forms.Robert Polidori for Metropolis

History – Bruce Gitlin, owner and CEO of MILGO BUFKIN, long desired to create origami in metal. If a delicate bird could be created from a sheet of paper, he wondered if a sheet of metal could be similarly folded to yield elegant new forms. Gitlin’s grandfather started MILGO/BUFKIN in 1916 as a truck body shop, and his father expanded the company to bend metal for architectural applications. Gitlin discontinued the truck work, added the fabrication of sculpture, purchased state-of-the-art equipment, and developed new technologies, growing the company exponentially. For the past forty years, MILGO/BUFKIN has continually introduced new materials, finishes, and technologies to support the innovations of leading architects, designers and artists. When Gitlin was searching for new approaches that would transform architecture in the new millennium, he met Dr. Haresh Lalvani, a prominent architect-morphologist, known for his use of higher dimensional mathematics to create structures based on new geometries. Dr. Lalvani has been a professor for the past thirty years at Pratt Institute, the New York based, internationally acclaimed school of art, architecture and design. Their serendipitous meeting began a collaboration that enabled Dr. Lalvani to combine decades of research and many patented inventions with MILGO/BUFKIN’s cutting-edge fabrication technologies. Their collaboration over four years of research and the filing of several patents led to AlgoRhythm Technologies, a division of MILGO/BUFKIN dedicated to the design, production, and marketing of a unique line of architectural products with curvilinear surfaces. The transformation of AlgoRhythm Technologies’ designs into products was facilitated by the metal working expertise of Alex Kveton, a sculptor with a fine arts and industrial design background. Also key to the effort was the computer modeling of Neil Katz, a former student of Lalvani’s and now an associate at Skidmore, Owings & Merrill. Katz used advanced software to translate Dr. Lalvani’s algorithmic concepts into computer models used to manufacture the products and to generate some of the images used in this brochure. The images were then computer-rendered by Mohamad Al-Khayer and Ajmal Aqtash, former and current students respectively. Dr. Lalvani’s new architectural forms can transform the design field, for they facilitate the creation of endless variations of integrated design environments with innovative, curvilinear surfaces. For AlgoRhythm Technologies’ potential economic impact and industry-leading ideas, New York State recognized the project in 2008 with a coveted NYSTAR (New York State Office of Science, Technology and Academic Research) grant in affiliation with Pratt Institute. Bruce Gitlin and Dr. Haresh Lalvani have created a new architectural language grounded in nature and higher mathematics. They have gone far beyond their initial search for origami in metal.

HARESH LALVANI, Ph.D. AlgoRhythm Technologies is the culmination of Dr. Haresh Lalvani’s career in combining architecture and higher mathematics to create a new architectural vocabulary of surfaces, especially in metal. A professor at Pratt Institute for the past thirty years where he has influenced generations of designers and architects, Dr. Lalvani holds a Ph.D. in Architecture from the University of Pennsylvania. Known worldwide for his morphological, structural, and design innovations, he serves on the editorial boards of Space Structures, (U.K.), and Structural Topology (Canada). He is also affiliated with The Structural Morphology Group (European-based), the International Association of Shell and Space Structures, the Japan Institute of Hyperspace Science, and ISIS-Symmetry (Hungary). An award recipient from the Graham Foundation for Advanced Studies in Fine Arts, the National Endowment for the Arts, and the National Institute for Architectural Education, Dr. Lalvani continues his groundbreaking work as an artist-in-residence at the Cathedral of St. John the Divine in New York and as the Co-Director of the Center for Experimental Structures at the School of Architecture, Pratt Institute. He is a MILGO/BUFKIN Design Fellow. Dr. Lalvani holds numerous patents that combine morphology, mathematics, and design. From his playful and challenging Metapuzzles to his discovery of Hyper-Geodesic Structures for architecture, he has combined his love of both art and mathematics to generate new languages of design. © Milgo Industrial Inc., 2002

Contact:

MILGO/BUFKIN

68 Lombardy Street

Brooklyn, NY 11222

Voice: 718-388-6476

Fax: 718-963-0614